The first device to be identified as a gun was a bamboo tube that used gunpowder to fire a spear.

By the late 1300’s handguns became known across Europe and were fired by holding a burning wick to a “touch hole” in the barrel igniting the powder inside, often requiring a prop to steady the gun.

A trigger did not appear on a firearm until the development of the matchlock gun - the first dated illustration of one dates to 1475, making it the first firearm with a trigger. In a matchlock gun, powder is held in a flash pan and is ignited by a wick, or match, in a movable clamp. This enabled both hands to remain on the gun, vastly improving aim.

The next major advance came in 1509 with the development of the wheellock which was capable of generating a spark mechanically. With no wick to keep lit, the wheellock was more user-friendly and reliable than the matchlock. However, matchlocks remained in common use into the 16th century because of the prohibitive cost of manufacturing a wheellock.

In 1630, the flintlock solved a longstanding problem. Some time in the late 1500s, a lid was added to the flash pan design. To expose or protect the powder, the lid had to be moved manually. The flintlock mechanism was designed to

push back the lid and spark a flint at the same time. The flintlock ignition system reigned for two centuries, with virtually no alteration.

The next major change for the trigger came in the early 1800s. In 1807, the percussion-detonating principle was patented and by 1825 percussion-cap guns were in general use. Triggers now used a sear surface to hold back a hammer that had enough force to detonate a percussion cap.

The development and improvement of the trigger has had a direct impact on improving the accuracy and precision of firearms. However, since the invention of the matchlock, triggers have operated on the principle of sliding friction - a trigger lever is used to slide the sear surface away from the hammer to the point where the hammer releases (the “break”). However, the trigger introduced a new problem to shooters: creep. Creep is the rearward displacement of a trigger that occurs before the sear releases. Creep is not to be confused with take-up, which is the rearward movement of the trigger during the first stage of a two-stage trigger. A two-stage trigger could only exhibit creep in its second stage.

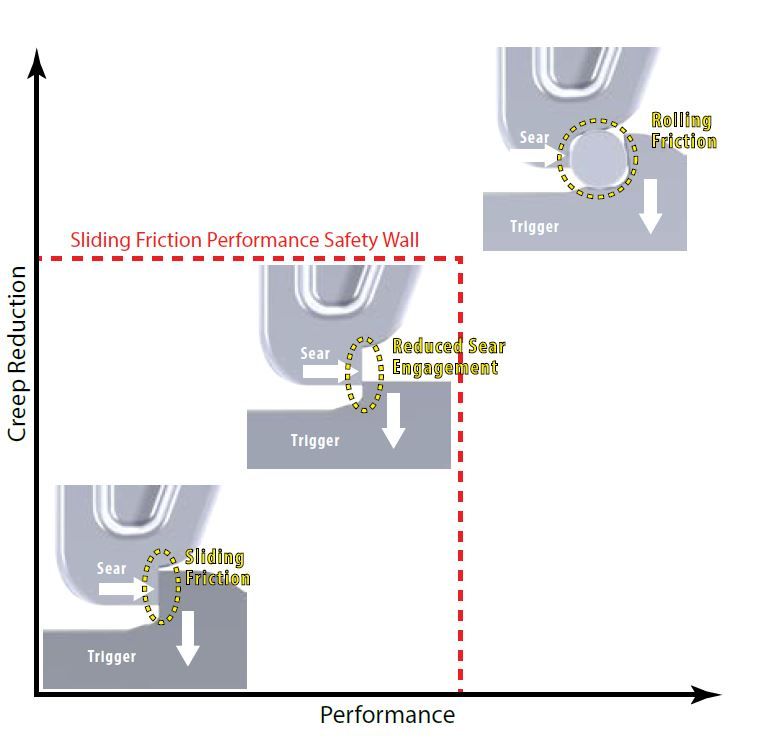

Creep has become a more noticeable issue as the boundaries of long range shooting continue to be pushed. Several companies have made significant improvements to the sliding friction trigger and have taken it to the point of perfection where creep is almost indiscernible. While many companies have taken their own novel approaches, they all involve improving performance by reducing creep through decreasing the amount of sear engagement. The trouble with decreasing sear engagement is that you can only go so far before safety becomes a concern. As sliding friction triggers have seen little change since Jewell in 1985 and the Accutrigger in 2002, it seems as through they have been taken to their potential.

However, creep is detectible in all sliding friction triggers because the trigger and the sear must slide apart for the gun to fire. While many would say that the technology was good enough, the desire to eliminate creep entirely lead to the creation of TriggerTech, a Canadian company that has developed the first trigger that operates on true rolling friction.

Mats Lipowski was whitetail hunting with a crossbow when a beautiful buck walked into range. Mats lined up on the buck and began to squeeze through the creepy, nine-pound trigger. The bolt was off, but it was not a clean trigger pull. Mats, a former competitive shooter, had missed a buck broadside at 40 yards because of this trigger’s performance. Mats just knew there had to be a better way. After talking it through with longtime friend and fellow mechanical engineer Greg Baniak, the two set out not just to improve the trigger, but to reinvent it.

The first prototype of TriggerTech’s Zero Creep Trigger was developed in 2012 for an Excalibur crossbow in Mats’ basement. It worked beautifully. The trigger was capable of withholding the 280 lb draw weight of the recurve crossbow, and enabled a shot to be fired with a 1.5lb trigger pull with zero creep. They knew they were onto something, but were just beginning to comprehend the many benefits and applications of Zero Creep technology.

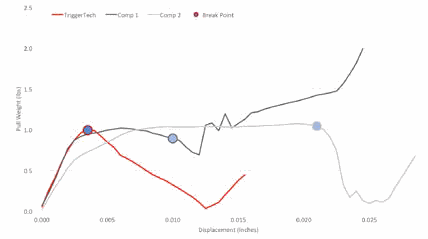

TriggerTech released a Remington 700 trigger featuring Zero Creep technology along with two other patented technologies at SHOT Show 2015 and it was the first bolt action trigger to eliminate creep. This was proven by a Dvorak TriggerScan™ System, a computer controlled motorized instrument designed to test trigger mechanisms of firearms. The system provides precise and repeatable graphical evidence of trigger performance. These are the trigger scans that show how Zero Creep technology has pushed the envelope of trigger performance even farther. The graph below shows the travel required at 1.0 lb release point for the TriggerTech Special Trigger (Red Line) in comparison with two leading R700 trigger manufactures. The TriggerTech release at 2-3 thousandths of an inch. Leading competitor 1 (dark grey) requires 10 thousandths movement with a rounded top characteristic. Leading competitor 2 (light grey) requires approximately 20 thousandths of movement with a large flat top characteristic.

People often fixate on a trigger’s pull weight, yet they are only looking at half of the equation. The other half is the distance, or creep, that you have to pull through at that weight. If you multiply the force by the distance, you get the energy that is required to operate a trigger. The operational energy of a trigger is represented by the area under a Dvorak curve and this can be described as how a trigger feels. The less energy you need to operate your trigger the more accurate you are going to be because you are required to put in less energy to fire the gun and you can be more precise with your trigger control.

Zero Creep Technology makes it possible to engineer a true zero creep break and to minimize component movements, resulting in the lowest operational energy possible.

When you are trying to increase the performance of a trigger you must always keep safety in mind. Sliding friction triggers force one to trade off sear engagement and spring weight with safety. In a Zero Creep trigger the level of engagement is fixed. The operator may adjust the pull weight to suit their needs, but does not need to think about sear engagement. The other safety advantages of a Zero Creep trigger are:

- It is not possible to preload the trigger; and

- Rolling friction means negligible wear so that the sear surface will not wear at the same rate of a sliding friction trigger.

The operation of the safety in a TriggerTech is also quite innovative. Most triggers have a safety that either prevents the sear from dropping or the trigger lever from moving. TriggerTech has engineered a safety that does both.

A well-known pitfall with high-end friction-based triggers is their performance in harsh environments. You would be hard-pressed to find a serious hunter or competitive shooter who does not have a story about their trigger going down at the wrong time due to contamination. We see another huge advantage of rolling friction triggers over sliding friction triggers in their ability to handle contamination.

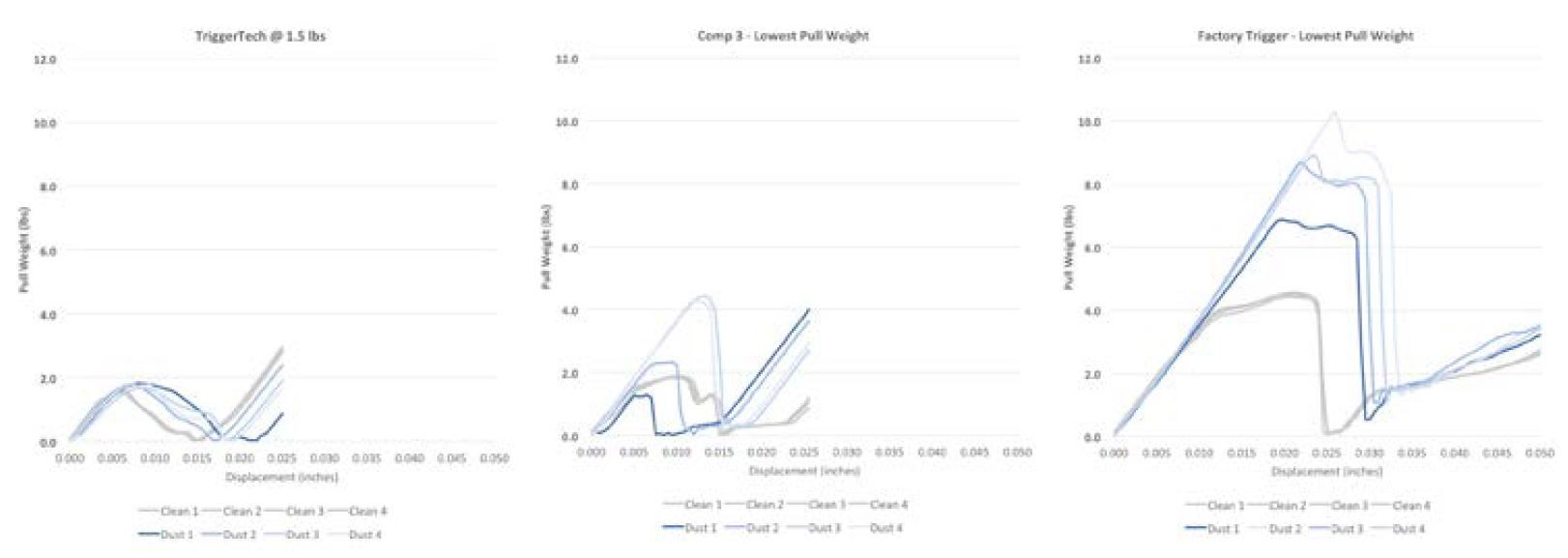

TriggerTech does extensive contamination testing and the benefits of using rolling friction are clear. The Dvorak scans above compare a trigger's ability to handle dust contamination. The first four shots show the performance of a clean trigger. The next four shots show the first four shots following equivalent dust impregnation. Comp 3 was introduced to this test as Comps 1 and 2 were inoperable following dust impregnation. Comp 3 was set at its lowest pull weight so for the purposes of comparison the TriggerTech primary was used at its lowest pull weight setting.

Following dust contamination, the TriggerTech Primary continues to deliver an exceptional break and exhibits only a minor increase in pull weight and operational energy. Comp 3 and the Factory trigger both exhibit increases in pull weight and operation energy in the magnitude of 100%.

While the gun existed for almost 500 years without a trigger, it would be hard to imagine a gun without one today. Over the past seven centuries, the development and advancement of the trigger has played a huge role in pushing the boundaries of what firearms are capable of. The next big step forward seems to be here with the rolling friction trigger. While this technology is just starting to make its impact, one thing is clear: creep is gone and it will not be missed.

Killing Creep